-

Three-Dimensional Warehousing Logistics System

LTCC01

Send Email Details

The Three-Dimensional Warehousing Logistics System is an intelligent, space-optimized solution designed to revolutionize inventory management and material handling in modern warehouses. Leveraging vertical storage racks, automated guided vehicles (AGVs), robotic arms, and AI-powered inventory tracking, the system maximizes storage density by utilizing multi-level shelving and dynamic retrieval mechanisms. Real-time IoT sensors and cloud-based analytics enable seamless monitoring of stock levels, order fulfillment, and equipment status, while autonomous navigation ensures efficient movement of goods from receiving to shipping. Its modular design supports flexible scalability for industries ranging from e-commerce and manufacturing to cold chain logistics, reducing operational costs, minimizing human error, and accelerating delivery times in a compact footprint. -

Shelves

HJ01

Send Email Details

Shelves are versatile storage structures designed to organize, display, and store items efficiently in residential, commercial, or industrial settings. Constructed from materials such as wood, metal, plastic, or composite blends, they come in various forms—including fixed, adjustable, modular, or wall-mounted—to accommodate diverse spatial and functional needs. Modern shelves often integrate smart features like weight sensors, LED lighting, or IoT connectivity for real-time inventory tracking, while ergonomic designs prioritize accessibility and space optimization. From bookshelves and retail display racks to warehouse pallet shelving, these systems enhance organization, maximize storage capacity, and contribute to aesthetically pleasing environments. Durable and customizable, shelves are essential tools for improving productivity and order in any workspace. -

Stacker

DDJ01

Send Email Details

A stacker is a specialized material handling device designed to efficiently lift, stack, and organize goods in warehouses, distribution centers, or manufacturing facilities. Equipped with forks, platforms, or grippers, it automates the vertical transportation of pallets, boxes, or heavy items, optimizing storage density and reducing manual labor. Stackers come in various configurations—including manual, semi-electric, and fully automated models—to suit different load capacities (up to several tons) and operational needs. Advanced stackers integrate sensors, AI-driven navigation, and IoT connectivity for real-time tracking, collision avoidance, and seamless integration with warehouse management systems (WMS). By enhancing safety, speed, and space utilization, stackers are indispensable tools for modern logistics and supply chain efficiency. -

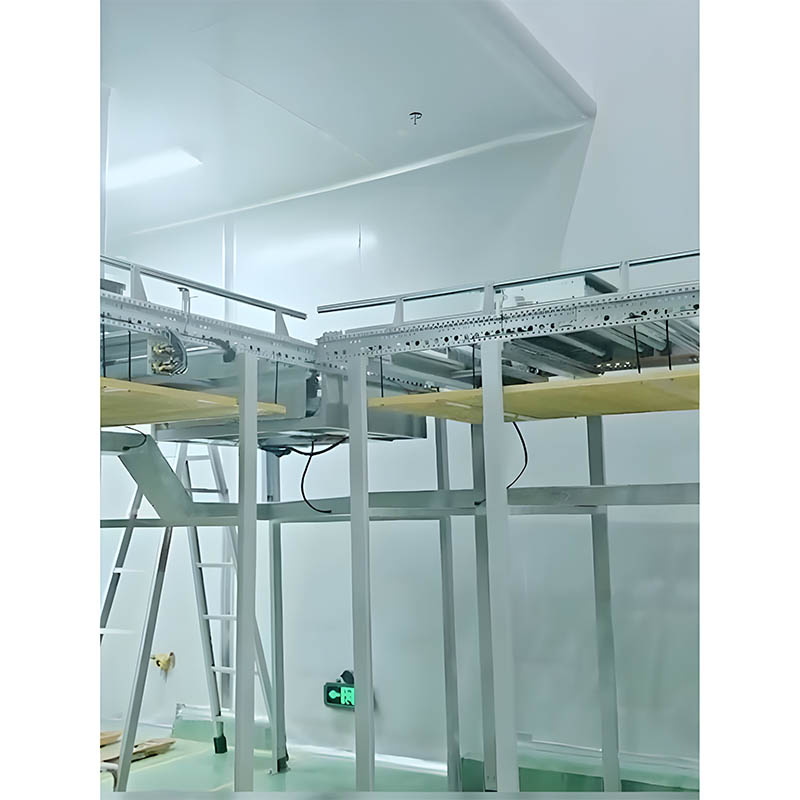

Conveying Module

SSMK01

Send Email Details

A conveying module is a standardized, customizable component designed to automate the seamless transportation of materials or products within industrial systems, such as assembly lines, warehouses, or packaging facilities. Comprising key elements like belt drives, roller systems, motorized chains, or pneumatic tubes, it ensures efficient, continuous flow of items ranging from small parts to heavy pallets. Modern conveying modules integrate smart sensors, IoT connectivity, and adjustable speed controls to optimize material handling, monitor operational status in real time, and synchronize with adjacent equipment. Their modular design allows for easy reconfiguration, scalability, and integration into complex production layouts, making them essential for enhancing productivity, reducing labor costs, and maintaining consistent workflow in automated environments. -

Lifting Module

FJMKG01

Send Email Details

A lifting module is a versatile, precision-engineered component designed to automate vertical movement tasks in industrial automation, material handling, and robotic systems. It integrates a motorized drive (electric, hydraulic, or pneumatic), a robust lifting mechanism (scissor lift, telescopic arm, or lead screw), and safety features like overload protection and limit switches to ensure reliable, controlled lifting of loads ranging from lightweight components to heavy pallets. Modern lifting modules incorporate smart sensors, IoT connectivity, and programmable logic controllers (PLCs) for real-time monitoring, adaptive height adjustment, and seamless integration with conveyor systems or robotic arms. Their compact, modular design enables easy installation in confined spaces and scalability across diverse applications, from assembly lines and warehouse storage to automotive manufacturing and medical equipment handling, enhancing efficiency, safety, and precision in vertical motion control. -

AGV Car

AGV01

Send Email Details

An AGV (Automated Guided Vehicle) Car is a driverless, programmable transport unit designed to autonomously navigate and transport materials in industrial environments such as warehouses, factories, and distribution centers. Powered by electric batteries, it follows predefined paths or dynamic routes using advanced navigation technologies like laser guidance, magnetic tape, vision systems, or LiDAR, ensuring precise movement and obstacle avoidance. Equipped with load-handling attachments (e.g., forks, conveyors, or robotic arms), AGV Cars streamline logistics by automating tasks such as pallet handling, component delivery, and finished product transfer. Their integration with warehouse management systems (WMS) enables real-time tracking, task scheduling, and optimization of material flow, reducing labor costs, enhancing safety, and improving operational efficiency in smart manufacturing and flexible supply chains.