-

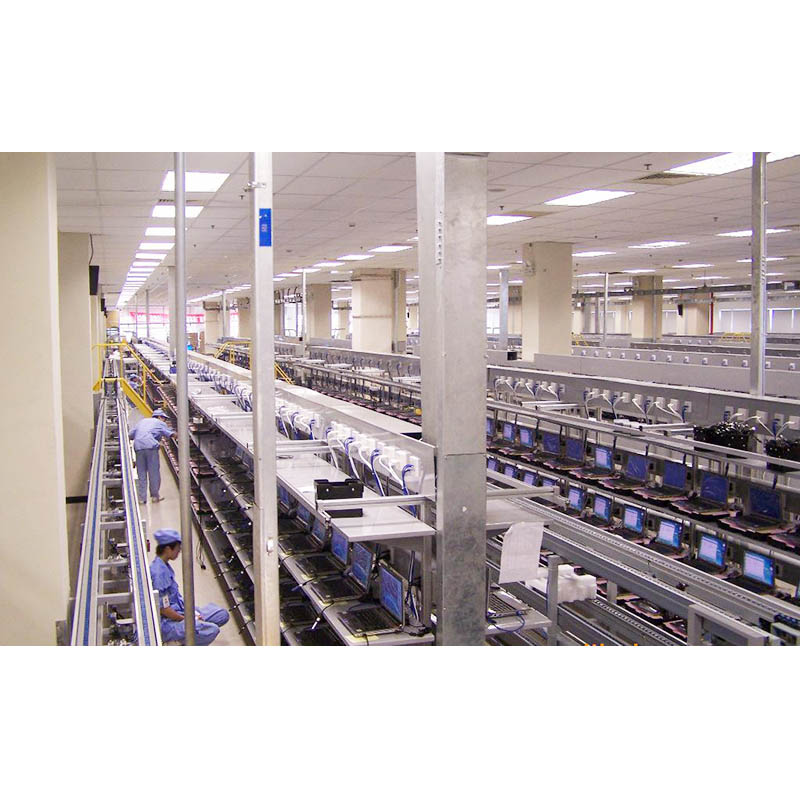

Laptop Automatic Production Line

BJBDN01

Send Email Details

The Laptop Automatic Production Line is a cutting-edge, fully integrated manufacturing system designed to streamline the assembly, testing, and packaging of laptops with unmatched precision, speed, and scalability. Leveraging advanced robotics, AI-driven quality inspection, and IoT-enabled real-time monitoring, the line automates critical processes such as motherboard soldering, component installation (CPU, RAM, storage), LCD panel bonding, and functional testing (boot-up, thermal management, and wireless connectivity). The system ensures consistent product quality through defect detection algorithms and adaptive process control, while minimizing human error and labor costs. It supports flexible customization for diverse laptop models, configurations, and form factors, enabling rapid transitions between production runs. By aligning with Industry 4.0 standards, this automated solution enhances production efficiency, reduces material waste, and accelerates time-to-market for global electronics manufacturers. -

Mobile Phone Automated Production Line

SJ01

Send Email Details

The Mobile Phone Automated Production Line is a highly sophisticated, Industry 4.0-compliant manufacturing system engineered to deliver precision, efficiency, and flexibility in smartphone production. Seamlessly integrating robotics, AI-powered vision inspection, and IoT-driven real-time analytics, the line automates critical processes—from PCB assembly, micro-component soldering, and camera module calibration to battery installation, casing integration, and multi-functional testing (touchscreen responsiveness, connectivity, and thermal performance). Adaptive algorithms ensure zero-defect quality control, while modular design allows rapid reconfiguration for diverse models, colors, and hardware specifications. This smart factory solution reduces labor dependency, minimizes material waste, and accelerates production cycles, empowering global brands to meet dynamic market demands with speed and sustainability.