-

Air Conditioning Automated Production Line

KT01

Send Email Details

The Air Conditioning Automated Production Line is a cutting-edge manufacturing system designed to streamline the assembly, testing, and packaging of air conditioning units with high precision and efficiency. Leveraging advanced robotics, AI-driven quality control, and integrated IoT sensors, this production line automates key processes such as component welding, refrigerant charging, leak detection, and performance testing. By minimizing manual intervention, it ensures consistent product quality, reduces production cycles, and enhances operational safety. The system supports flexible customization for diverse models and specifications while optimizing energy consumption and material usage. Ideal for large-scale manufacturing, this automated solution significantly boosts productivity, lowers costs, and aligns with Industry 4.0 standards for smart, sustainable production. -

Refrigerator Automatic Production Line

BX01

Send Email Details

The Refrigerator Automatic Production Line is a state-of-the-art manufacturing system engineered to optimize the assembly, testing, and packaging of refrigerators with unparalleled efficiency and precision. Utilizing advanced robotics, AI-powered quality inspection, and real-time IoT monitoring, the line automates critical processes such as inner liner forming, compressor installation, vacuum leak testing, and cooling performance validation. This seamless integration reduces human error, ensures consistent product quality, and accelerates production throughput. Designed for scalability, the system supports flexible customization of refrigerator models, sizes, and features while minimizing material waste and energy consumption. By aligning with Industry 4.0 principles, it delivers a smart, sustainable solution that enhances competitiveness for large-scale appliance manufacturers. -

Washing Machine Automatic Production Line

XYJ01

Send Email Details

The Washing Machine Automatic Production Line is a highly efficient, intelligent manufacturing system designed to streamline the production of washing machines from component assembly to final testing and packaging. Leveraging advanced robotics, AI-powered defect detection, and IoT-enabled process control, the line automates key processes such as drum assembly, motor installation, water leakage testing, and vibration analysis. This integration ensures consistent product quality, reduces production time, and enhances operational safety by minimizing manual intervention. The system supports flexible customization for various washing machine capacities, designs, and smart features while optimizing material usage and energy efficiency. Aligned with Industry 4.0 standards, it delivers a scalable, sustainable solution that boosts productivity and competitiveness for appliance manufacturers. -

Ceramic Toilet Automatic Production Line

TCMT01

Send Email Details

The Ceramic Toilet Automatic Production Line is a cutting-edge manufacturing system designed to revolutionize the production of ceramic sanitary ware with unparalleled efficiency, precision, and sustainability. Seamlessly integrating advanced robotics, AI-driven quality inspection, and precision molding technologies, the line automates every stage—from raw material dispensing and high-pressure molding to glaze application, kiln firing, and final assembly. Real-time IoT monitoring ensures optimal process control, minimizing material waste and energy consumption while maintaining consistent product quality. The system supports flexible customization for diverse toilet designs, shapes, and surface finishes, catering to both mass production and niche markets. By aligning with Industry 4.0 standards, this automated solution enhances productivity, reduces labor costs, and promotes eco-friendly manufacturing practices for the global sanitary ware industry. -

Smart Toilet Automatic Production Line

ZNMT01

Send Email Details

The Smart Toilet Automatic Production Line is a state-of-the-art manufacturing system tailored for the high-precision, high-efficiency production of intelligent sanitary fixtures. Seamlessly integrating advanced robotics, AI-powered quality inspection, and IoT-driven process optimization, this line automates every stage—from ceramic body molding and electronic component assembly to functional testing (e.g., bidet spray, seat heating, and sensor calibration) and final packaging. Real-time data analytics ensure strict adherence to quality standards while minimizing material waste and energy consumption. The system supports flexible customization for diverse smart toilet models, enabling rapid adaptation to market trends and consumer preferences. By aligning with Industry 4.0 principles, it delivers a scalable, sustainable solution that enhances productivity, reduces labor dependency, and accelerates the digital transformation of the sanitary ware industry. -

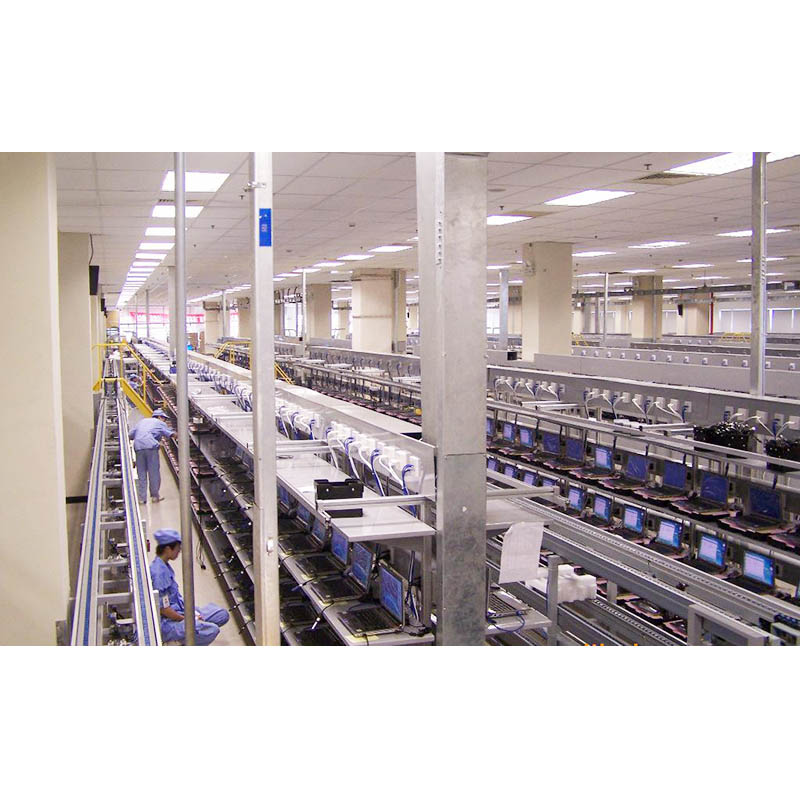

Laptop Automatic Production Line

BJBDN01

Send Email Details

The Laptop Automatic Production Line is a cutting-edge, fully integrated manufacturing system designed to streamline the assembly, testing, and packaging of laptops with unmatched precision, speed, and scalability. Leveraging advanced robotics, AI-driven quality inspection, and IoT-enabled real-time monitoring, the line automates critical processes such as motherboard soldering, component installation (CPU, RAM, storage), LCD panel bonding, and functional testing (boot-up, thermal management, and wireless connectivity). The system ensures consistent product quality through defect detection algorithms and adaptive process control, while minimizing human error and labor costs. It supports flexible customization for diverse laptop models, configurations, and form factors, enabling rapid transitions between production runs. By aligning with Industry 4.0 standards, this automated solution enhances production efficiency, reduces material waste, and accelerates time-to-market for global electronics manufacturers.